Hot:

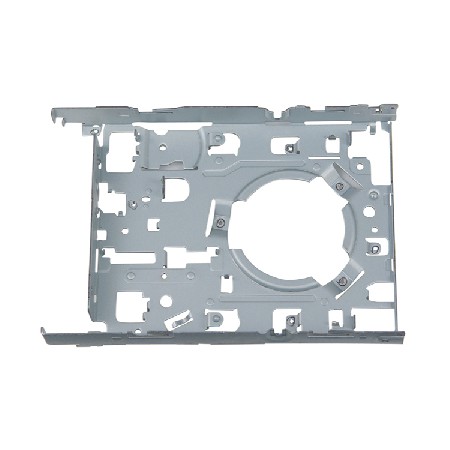

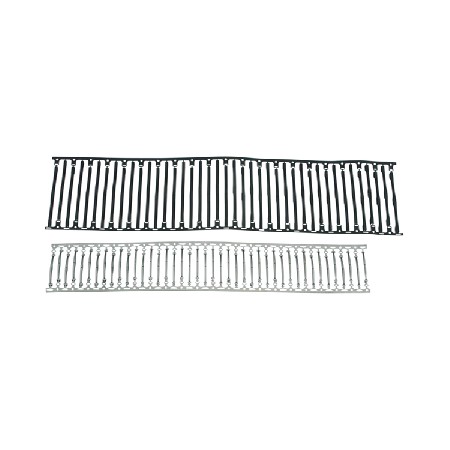

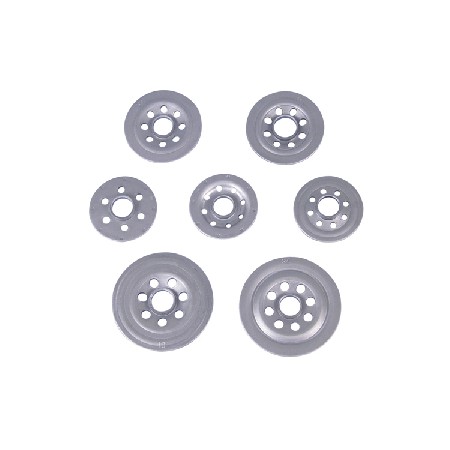

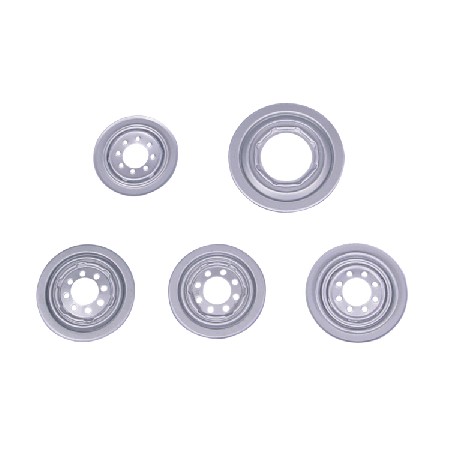

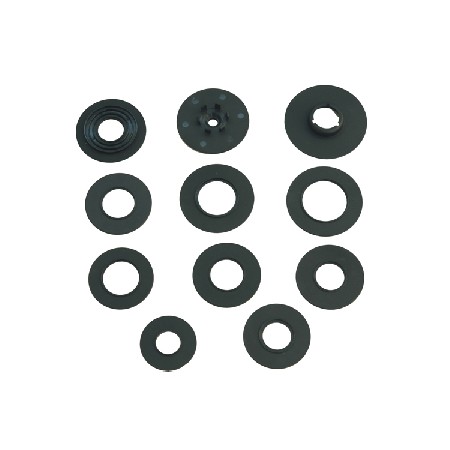

Hardware accessories injection molding accessories motorcycle accessories

PRODUCT

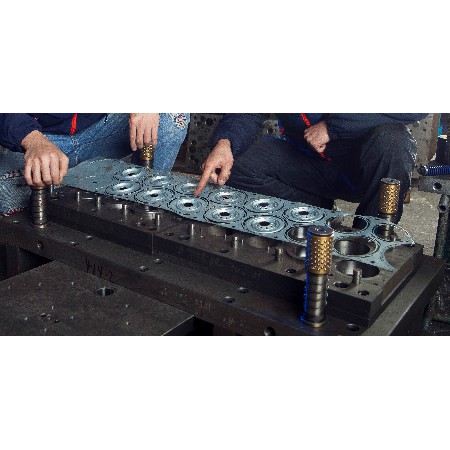

To undertake all kinds of precision hardware mold design and manufacturing, and all kinds of metal stamping products production

EQUIPMENT

With development department, technology department, production department, quality department, mold department, Marketing Department and other perfect department management system.

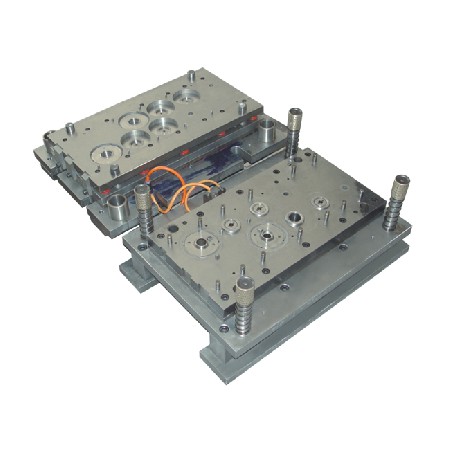

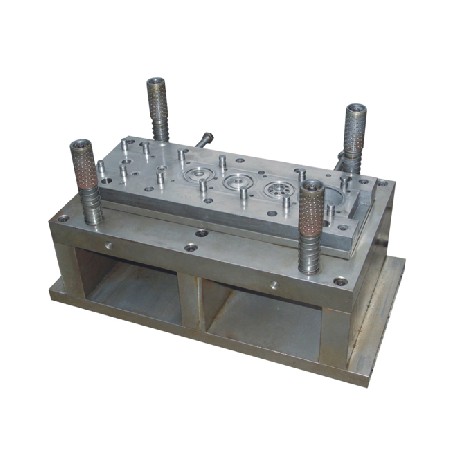

Mold workshop has lathe, milling machine, grinding machine, wire cutting EDM and a number of advanced equipment.And advanced manufacturing testing and processing equipment.

QUALITY

Main production: car audio, filter, wiper, stainless steel and other auto parts hardware stamping products.

set up a strict quality management system, perfect production structure.Has purchased a batch of advanced manufacturing testing processing equipment, to ensure the quality of products.

EXPERIENCE

Jiangmen Huaying Hardware & Electrical Appliance Co., Ltd., founded in 1991, is a foreign-funded enterprise integrating design, manufacturing, sales and service.

has a modern workshop of 5000 square meters, with 5 to 400 tons of automatic punch, single punch in total more than 60 sets.

WIN-WIN

According to the requirements of customers, we can undertake all kinds of precision hardware mold design and manufacturing, and all kinds of metal stamping products production.

to high standards, high quality production requirements to provide customers with quality products and satisfactory service.

ABOUT

A collection of design, manufacturing, sales, service in one of the foreign-funded enterprises

Jiangmen Huaying Hardware & Electrical Appliance Co., Ltd. was established in 1991.It is located at No.87, Section 6, West Zhongtai Road, Hetang Town, Pengjiang District, Jiangmen City, Guangdong Province.Is a collection of design, manufacturing, sales, service in one of the foreign-funded enterprises.Adhering to the "customer first, excellent quality" principle, dedicated to the general customer service.

The company mainly produces: car audio, filter, wiper, stainless steel and other auto parts hardware stamping products.The company has a modern workshop of 5000 square meters, with 5 to 400 tons of automatic punch, single punch in total more than 60 sets.With development department, technology department, production department, quality department, mold department, Marketing Department and other perfect department management system.

Our company can according to the customer's requirements, undertake all kinds of precision hardware mold design and manufacturing, and all kinds of metal stamping products production.

Mold workshop has lathe, milling machine, grinder, wire cutting EDM and a number of advanced equipment.In order to ensure the quality and delivery time, the company has set up a strict quality management system and perfect production structure.